Easy operating

Reliable production output

Pneumatic and hydralic dual control,energy saving and high efficiency.

Dual cylinder insurance device

High quality, more than 95% finished product rate

|

Automatic |

semi-automatic |

| Designed Capacity | 400-600kg/day |

| forming type | vacuum suction |

| Mould Material: | Aluminium Alloy:6061 |

| Raw material: | plant fiber pulp (any paper pulp) |

| Drying method | heating in mold(by eleatric or by oil ) |

| Auxiliary Equipment Power For Each Machine: | 19.5KW For Each Machine |

| Vacuum Requirement For Each Machine: | 6m3/min/set |

| Air Requirement For Each Machine: | 0.2m3/min/set |

| After-sales Service | Free spare parts, Video technical support, installation guidance, commssioning |

| Place of Origin | Xiamen city ,China |

| Finished Products: | Disposable ECO-friendly Tableware |

| Accepted Payment Type | L/C ,T/T |

| Accepted Payment Currency | CNY,USD |

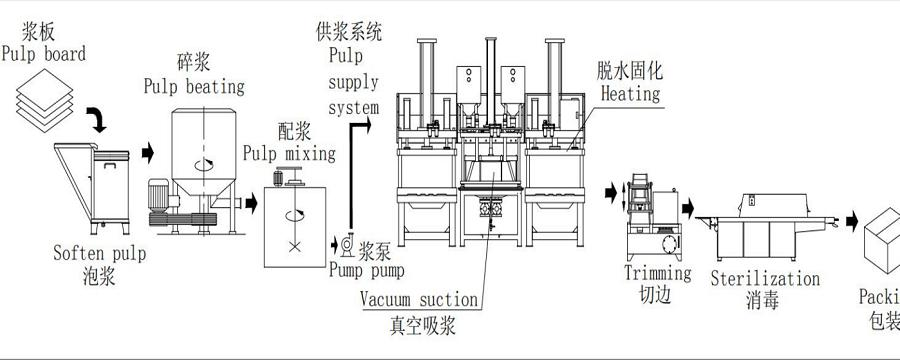

The DRY-2017 Semi-automatic pulp molding tableware machine is mainly applied for disposable plates, bowls, trays, boxes and other items for foodservice . It is energy saving, cost saving and trimming for the better edge after hot pressing process.

|

Product Type: |

Disposable Eco-Friendly Tableware Machine |

| Processing Type: | Pulp Molding Machine |

| Power(W): | 0.125KW(with the rob arm: 5.5KW) |

| Warranty: | 1 year |

| Condition: | New |

| After-sales Service Provided: | Field installation, commissioning and training |

| Place of Origin: | Fujian, China |

| Brand Name: | FAR EAST |

| Weight: | 9.5 Tons |

| Production Capacity: | about 500kgs/day( working hour: 23 hours per day) |

| Dimension(L*W*H): | 3940*1770*3400 mm |

| Applicable Industries: | Manufacturing Plant |

Pneumatic and hydraulic dual control energy saving, and high efficiency.,easy operating, high quality. High precision and durable molds. Dual cylinder insurance device.

|

Mould Material: |

Aluminium Alloy:6061 |

| Machine Weight: | 9.5T |

| Auxiliary Equipment Power For Each Machine: | 6m3/min/set |

| Air Requirement For Each Machine: | 0.2m3/min/set |

| Daily Output: | About 400-600kgs(23hours per day) |

Please fill in your true information and we will contact you as soon as possible