1.This machine applies PLC and touch screen, automatic feeding, electronic weighing, temperature control, material level control to realize automatic and continuous production.

2. Electronic weighing system and material level control system ensure the density of the foamed beads, which make the beads uniform and keep the density tolerance within 2%.

3. Japan original pressure reducing valve controls the steam pressure of the chamber, which ensures the outcome pressure of the valve constant and the inner temperature stable, which keeps the foamed material equal and prevents the beads agglomerate because of the bad temperature control.

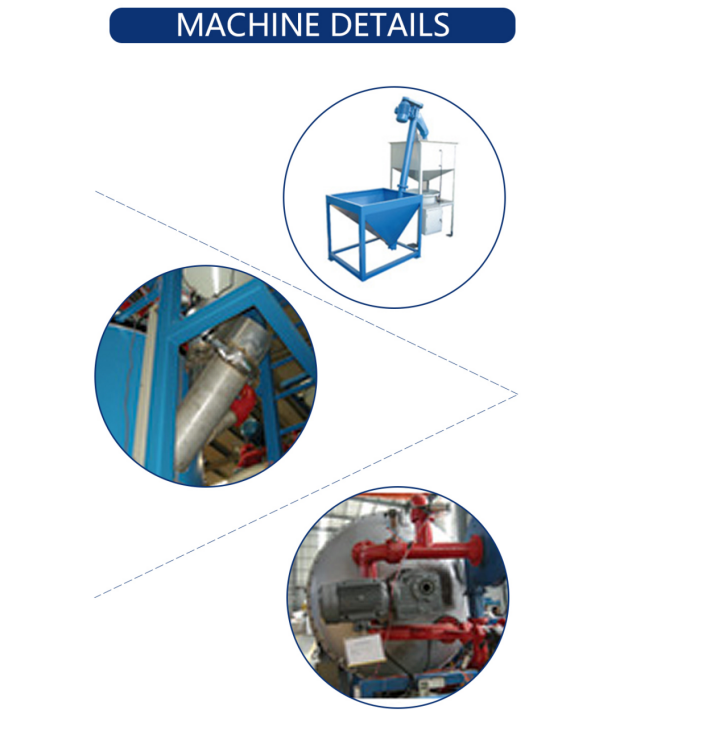

4. Automatic material charging system improves efficiency and reduces labor intensity.

5. The closed constant pressure foaming barrel has high heating efficiency. It can save more than 50% energy compared to the continuous pre-expander.

6. Automatic discharging from the pre-expander, which can automatically filter and crush the ball material and transport the foamed material to silos.

7. Most of the main component are world-famous brand, with reliable performance, stable quality, long service life and low maintenance cost.

8. The computer has memory function, which can record all information such as brands, specifications, expanding foam techniques and parameters of EPS material manufacturers. When customers want to use the materials that ever been used before just press the touch screen of computer to quickly go back to the original technique.

Main Feature of EPS shape moulding machine:

1. Pressure reduction valve from Japan used for steam control

2. Equipped with weighting sensor to increase density accuracy

3. Insulation expansion is available for lower density

4. Second expansion is available for lower density

5. Fluid bed is equipped with heater to shorten aging time

6. Five safety features to insure safe operation

7. Safety fence on top

|

DES |

Unit/ item |

SPJY1200 |

SPJY1400 |

SPJY1600 |

|

Chamber diameter |

mm |

1200 |

2000 |

2500 |

|

Chamber height |

mm |

2000 |

2000 |

2500 |

|

Volume |

mm3 |

2 |

2.7 |

5 |

|

Steam Pressure |

Mpa |

0.6 |

0.6 |

0.6 |

|

Density range

|

g/l |

6~25 |

6~25 |

6~25 |

|

Tolerance |

g/l |

±3% |

±3% |

±3% |

|

Capacity |

kg/hr |

200-800 |

600-1000 |

600-1800 |

|

Power |

KW |

17.5 |

22 |

26 |

|

Voltage |

V/Hz |

380/50 |

380/50 |

380/50 |

|

Contour size |

mm |

5600*3100*4200 |

7600*3500*5000 |

7600*3700*6000 |

|

Weight |

Kg

|

3500 |

4500 |

5500 |

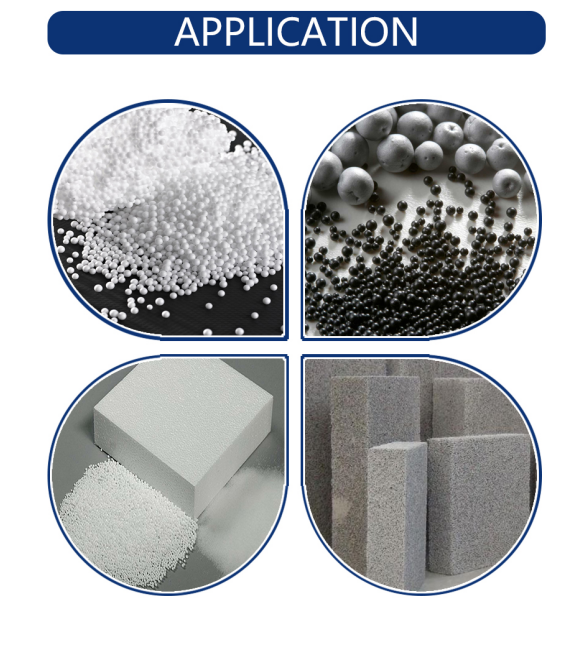

Q. Are you EPS foam block cutting machine factory or trading company? A: We are a EPS foam machine manufacturing factory located in yantai, shandong. We are professional in EPS foam block cutting machine, EPS foam block molding machine, EPS foam box wrapping machine and so on.

Q. How can I get your factory? A: By air: You can take a plan to YANTAI airport from China, if you fly from Korea ,Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us. By Train: You can stop at YANTAI station.

Q. Do you provide pick-up service? A: Yes, of course. If you are in Yantai airport or station, we can arrange a special car to pick you up directly to our factory.

Q. Do you accept EPS Foam Machine customization? A: Yes, of course. We can adjust our EPS foam all kind of machine's parameter, design and size to be suitable for your EPS foam block or box or other products.

Q. How long is your polyurethane foam casting machine warranty? A: 1 year. Within one yea, if it is not man-made damage, we will provide free replacement parts, but the shipping cost needs to be paid by the customer.

Q. What if I can't install it after I get the EPS foam cutting, molding or other machine? Do you offer installation services? A: Yes, we supply video technical support. If your company has engineer, you can come to our factory, we will provide field installation, commissioning and training. Of course, our engineers are available to service machinery overseas.

Q. What is your terms of payment? A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance. Other payment terms can also be negotiated.

Q. What is your terms of delivery? A: EXW, FOB, CFR, CIF.

Q. How about your delivery time? A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q. Can you produce according to the samples? A: Yes, we can produce mold by your samples or technical drawings.

Q. Do you test all your machines before delivery? A: Yes, we have 100% test before delivery.

Q. Do you have some videos where we can see the line producing? A: Yes, we can provide some videos for reference.

Q: How do you make our business long-term and good relationship? A:1. We keep good quality, competitive price and 24 hours one to one service to ensure our customers benefit ;

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Please fill in your true information and we will contact you as soon as possible