|

Model |

Unit |

EPE105 |

EPE120 |

EPE150 |

EPE170 |

EPE180 |

EPE200 |

EPE220 |

|

Screw diameter L/D |

|

105/55:1 |

120/55:1 |

150/55:1 |

170/55:1 |

180/55:1 |

200/55:1 |

220/55:1 |

|

Screw speed |

r/min |

5-45 |

5-45 |

5-45 |

5-45 |

5-45 |

5-45 |

5-45 |

|

Foam rate |

|

20-40 |

20-40 |

20-40 |

20-40 |

20-48 |

20-48 |

20-48 |

|

Width of product |

mm |

1000-1500 |

1000-2000 |

1000-2000 |

1000-2000 |

1000-2000 |

1000-2000 |

1000-2000 |

|

Thickness of product |

mm |

0.5-6.5 |

0.8-8 |

1-12 |

2-16 |

2-18 |

3-20 |

4-25 |

|

Cooling method |

|

|

|

|

|

|

|

|

|

total power |

|

130 |

170 |

240 |

285 |

320 |

350 |

420 |

|

Dimensions (L×W×H)(approx) |

m |

23×2.3×2.2 |

25×2.3×2.2 |

30×2.3×2.2 |

32×2.3×2.2 |

34x2.8x3.5 |

38x2.8x3.8 |

45x2.8x3.8 |

|

Total weight (approx) |

t |

9 |

12 |

15 |

17 |

15.5 |

18 |

22 |

Special Neck :Cooling water jack,prevent material sticking at the inlet of hopper when material injecting.

Screw And Barrel: 38CrMoAlA nitrogen treatment.

Method of heating:cast aluminum heater

Method of cooling: inner and outer water cooling pipe.

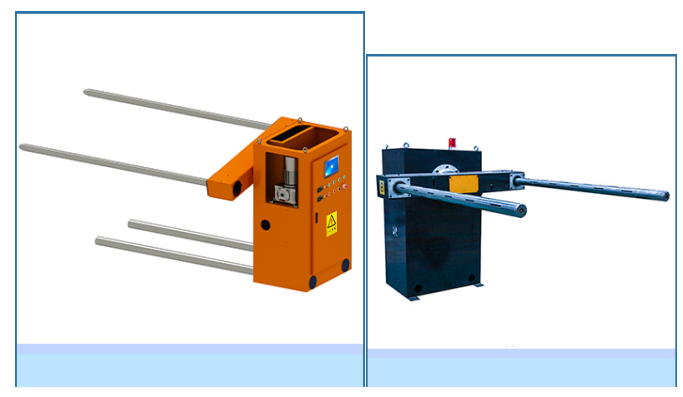

Air ring & shaping drum unit aluminum air ring, you can adjust air direction and air flow according to production.The air is more uniform. The aluminum material is more wearable.Cooling method:wind cooling Methods for cutting open: round cutter motor driven Shaping drum size: customer product decided

Install static electricity eliminator under haul-off unit (ion fan). \ The black one Material of expanding roller: stainless steel Material: STPG tube hard chrome plating

Model: Double axis cantilever displacement Type(air shaft type)

Maximum of rolling weight: Maximum 30kg×1m(diameter))

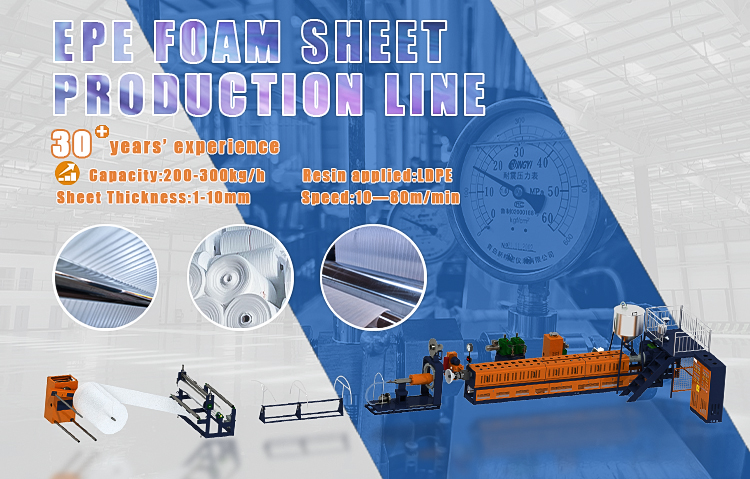

Q:Why are many pictures on the Internet the same as your company?

A:Because our company has been specialized in plastic machinery for more than 30 years, after years of exploration and continuous research, the appearance of the equipment and the ease of use have led the Chinese plastic machinery industry,it is inevitable to be stolen by competitors, but our core technology is not something that everyone can learn.

Q:Why I choose your company?

A:(a) We are the Leading foam machine Manufacturer in China.

(b) We have made foam machine about 30 years with strong experience and advanced technology.

(c) Best Quality & Best Service with Competitive price.

(d) 100% inspection Before Shipment, and got CE certificate.

(e) We have Professional technical team, supply 24 hours service.

Please fill in your true information and we will contact you as soon as possible